How to produce chewing gum

Published February 18, 2026

Resource

Formulation Guidance

The video will show you the entire manufacturing process of chewing gum at our pilot facility @ROQUETTE EU/Lestrem, including the mixing, extrusion, and continuous rolling and scoring line. It will give you an idea of how gum manufacturers do it.

Speakers

André Busolin

Confectionery Scientist, Roquette

This video contains file footage filmed prior to the COVID-19 pandemic.

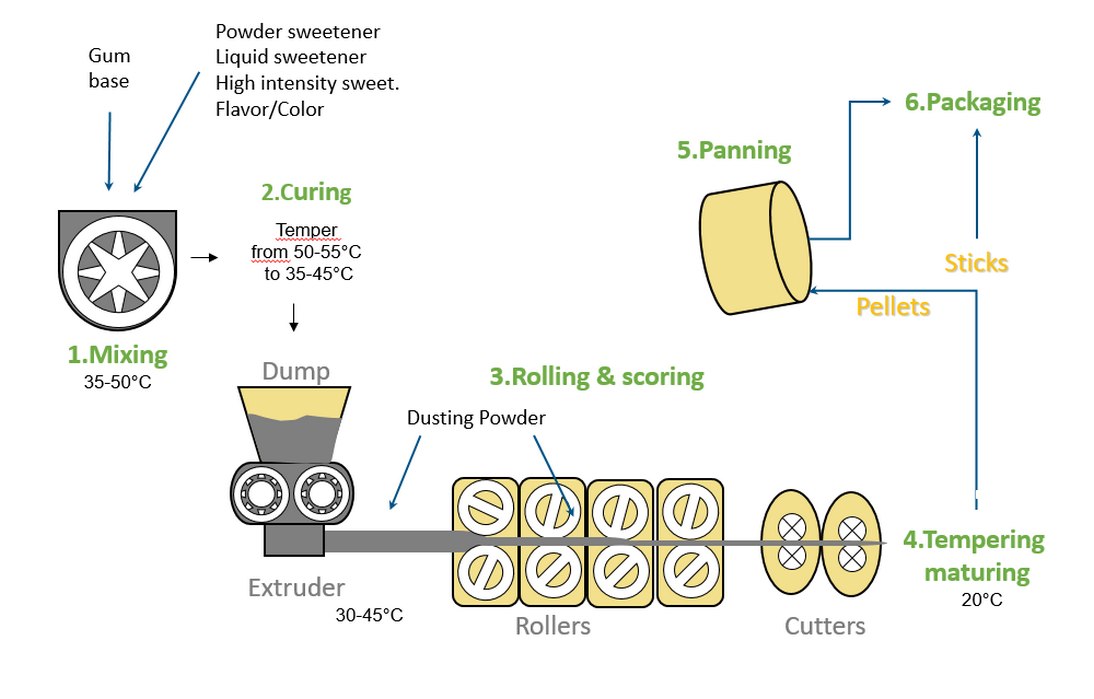

The key steps in chewing gum production are the following:

- Mixing: formation of a dough through the mixing of chewing gum base, powder (NEOSORB® sorbitol , SweetPearl® maltitol, XYLISORB® xylitol, mannitol powders) and liquid sweetener (LYCASIN® maltitol syrup, NEOSORB® sorbitol syrup); high-intensity sweeteners, flavor and color in this order.

- Curing: cooling of the dough obtained to have the consistency suitable for extrusion.

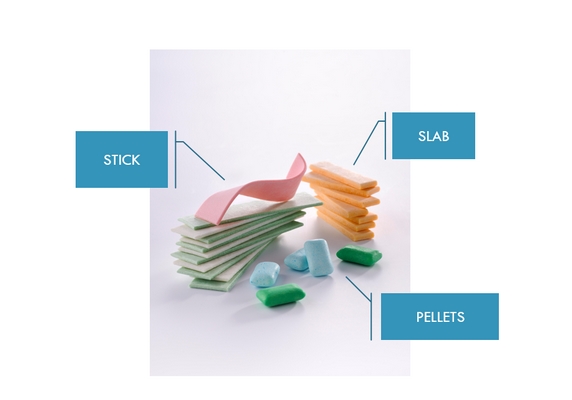

- Rolling and scoring: the dough is laminated and cut lengthwise and widthwise to get the “pellets” or “slabs or “gum sticks”.

- Tempering: As the mixture has been heated, it needs to be cooled down. This step allows reorganization of the molecules in the gum mass and the hardening of formed units.

- Coating or panning: multiple micro-layers of polyols (SweetPearl® maltitol, NEOSORB® sorbitol, XYLISORB® xylitol ) are applied to form the coating.