How to Produce a High Fiber Powder Drink

Published February 17, 2026

How to Produce a High-Fiber Powder Drink

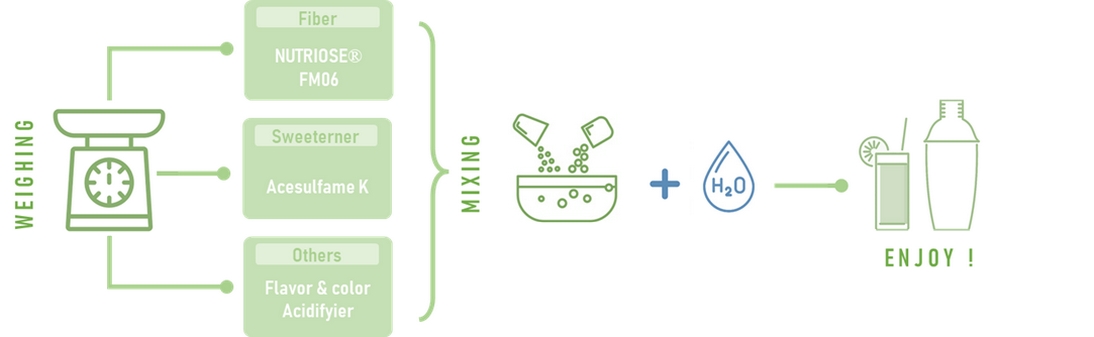

The first step shows the weighing of the different powders:

- NUTRIOSE® FM 06 soluble fiber, which has a good flowability and particle size, to reach the high-fiber claim

- Flavors and coloring agents to enhance the taste and aspect of the final product

- Intense sweeteners to produce a sweet sugar-free beverage

- Citric acid to lower the pH and have a refreshing final product

The second step is about the mixing of the ingredients using specific equipment called TURBULA® 3D motion blender (Willy A. Bachofen AG) to achieve a homogeneous powder blend.

Blending of ingredients can be achieved through other blenders such as ribbon blenders or ploughshare blenders.

For bigger batch size, you will have to consider to premix separately the ingredients below 1% in the recipe to ensure good homogeneity in the blend. This premix will be introduced in the blender following this sequence: half of NUTRIOSE®, premix, second half of NUTRIOSE®.

Particle size distribution and color evaluation tests are carried out on the powder preparation to control the quality of the final product.

To enjoy this high-fiber drink, the powder will be added to water and easily dissolved. Due to the high solubility of NUTRIOSE® FM 06, the final beverage is clear, without any lumps or clouding effect.

It is now easy to reach your nutritional goals thanks to the clinically proven benefits on digestive health and blood glucose management of 8g of NUTRIOSE® soluble fiber per day.