How to Produce a Plant-Based Ready-to-Drink Beverage

Published February 28, 2026

This video shows how to produce a high protein plant-based ready-to-drink beverage using NUTRALYS® S85 Plus pea protein.

This video shows how to produce a high protein plant-based ready-to-drink beverage using NUTRALYS® S85 Plus pea protein.

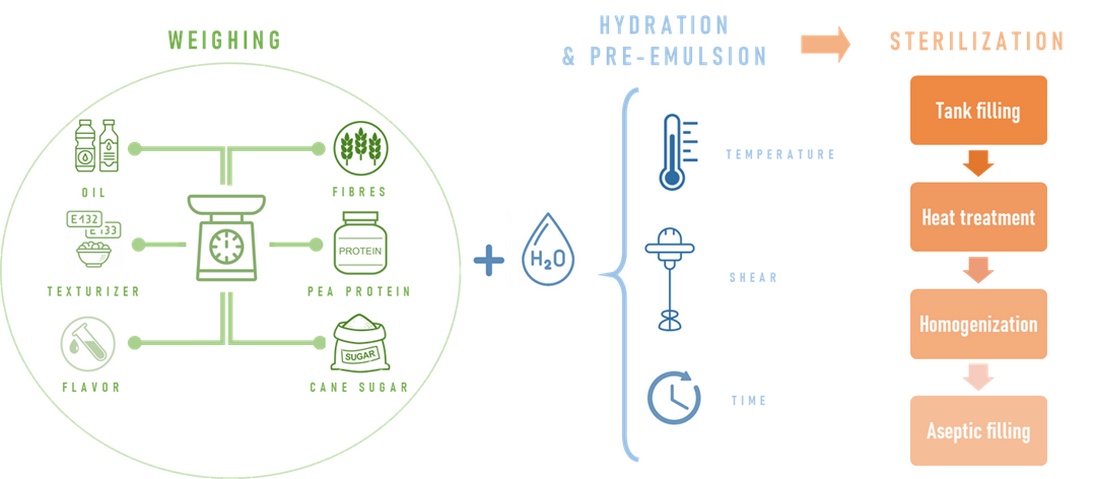

The first step shows the weighing of the different powders:

- NUTRALYS® S85 Plus-N pea protein to increase the protein content in the final product. The low viscosity and the good heat resistance are two keys’ properties for ready-to-drink beverages.

- NUTRIOSE® FM 06 soluble fiber to increase the fiber content,

- Sugar to improve the sensory attributes of the drink,

- Oil for the smoothness and nutritional purpose , lecithin to create a good emulsion,

- Texturizers to improve the stability and the mouthfeel,

- Flavors to enhance the taste of the final product.

The second step is about the hydration of the dry ingredients, using specific mixing equipment and parameters:

- Use water temperature to 50°C to optimize the solubility of the NUTRALYS® pea protein,

- Use low shear to dissolve well the different powders and avoid foam creation,

- Manage the time of hydration to enhance the solubilization of the NUTRALYS® pea protein.

The third step is the addition of the oil phase into the water phase; it is also called the pre-emulsion. Time and shear will be also key in this phase.

The last step is the heat treatment using a pilot plant UHT equipment where both NUTRALYS® S85 Plus-N pea protein, NUTRIOSE® FM 06 will not be impacted in their quality thanks to their strong stability over processes:

- Tank filling with the previous hydrated mix,

- Sterilization at 142°C to reduce microbiological activity,

- High-pressure homogenization step to improve the emulsion and improve the smoothness of the ready-to-drink beverage over time.

- Bottle aseptic filling.

This is the best way to produce a nutritious ready-to-drink beverage using a sustainable source of plant protein and to support muscle health.