Troubleshooting and FAQs for PEARLITOL® Mannitol

Published February 11, 2026

Frequently asked questions for PEARLITOL® mannitol and its applications

-

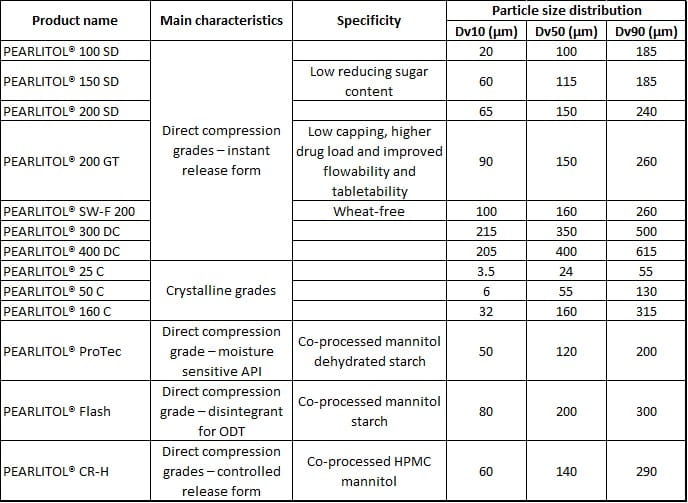

PEARLITOL® C is the crystalline form of mannitol which typically undergoes further granulation before tableting. PEARLITOL® SD, GT and DC grades are designed for direct compression. The granular powders of PEARLITOL® SD, PEARLITOL® GT and PEARLITOL® DC are prepared by spray-drying and extrusion respectively.

-

PEARLITOL® SW-F 200 is a wheat-free mannitol for direct compression. For more information on its physical properties, you may refer to its product profile.

-

PEARLITOL® 200 INH mannitol is specially designed for inhalation.

-

PEARLITOL® 25 C, PEARLITOL® 50 C and PEARLITOL® 160 C have different particle sizes but are otherwise exactly the same product. The mean particle size of PEARLITOL® 25 C, PEARLITOL® 50 C and PEARLITOL® 160 C are approximately 25 µm, 50 µm and 160 µm respectively.

-

-

For more information on the physical properties, you may refer to the product profile on PEARLITOL® 160 C.

-

For more information on the physical properties, you may refer to the product profile on PEARLITOL® 25 C.

-

For more information on the physical properties, you may refer to the product profile on PEARLITOL® 50 C.

-

Typical specific surface areas of PEARLITOL® grades for direct compression are:

PEARLITOL® 100 SD: 1.05 m²/g

PEARLITOL® 150 SD: 1.3 m²/g

PEARLITOL® 200 SD: 1.2 m²/g

PEARLITOL® 200 GT: 1.3 m²/g

PEARLITOL® 300 DC: 0.4 m²/g

PEARLITOL® 400 DC: 0.45 m²/g

PEARLITOL® ProTec: 1.6 m²/g

PEARLITOL® Flash: 0.55 m²/g

PEARLITOL® CR-H: 0.8 m²/g -

PEARLITOL® C consists of beta crystals of mannitol, which has been shown to be stable under practical conditions.

-

A reference value is available on its product profile page.

Note that the values obtained from the measurement of particle size distribution is known to vary between methods and equipment. Since each method has its own working principles and inherent limitations, the results obtained may be highly dependent on and/ or specific to the method employed. Comparisons between samples should be made when the same method/ procedure is employed. -

A reference value is available on its product profile page.

Note that the values obtained from the measurement of particle size distribution is known to vary between methods and equipment. Since each method has its own working principles and inherent limitations, the results obtained may be highly dependent on and/ or specific to the method employed. Comparisons between samples should be made when the same method/ procedure is employed. -

A reference value is available on its product profile page.

Note that the values obtained from the measurement of particle size distribution is known to vary between methods and equipment. Since each method has its own working principles and inherent limitations, the results obtained may be highly dependent on and/ or specific to the method employed. Comparisons between samples should be made when the same method/ procedure is employed. -

For more information on the physical properties, you may refer to the product profile of PEARLITOL® 200 INH.

-

For more information on the physical properties, you may refer to the product profile on PEARLITOL® CR-H.

-

For more information on the physical properties, you may refer to the product profile on PEARLITOL® ProTec.

-

The co-process with mannitol confers HPMC better flowability and compactibility than pure HPMC, while keeping high controlled release performance.

-

Both PEARLITOL® ProTec and Flash are co-processed mannitol-starch containing approximately 80% of mannitol and 20% of extra white maize starch. However, contrary to PEARLITOL® Flash, the maize starch used for PEARLITOL® ProTec is dehydrated prior to being co-processed with mannitol. This additional step leads to a low water activity (0.2) and a lower water content (2% water content max. for PEARLITOL® ProTec vs. 3% water content max. for PEARLITOL® Flash).

With its low water activity, PEARLITOL® ProTec is designed for the direct compression of moisture sensitive ingredients such as probiotics and vitamins.

PEARLITOL® Flash offers disintegrant properties and pleasant taste and texture particularly appraciated in orally dispersible tablets.

-

PEARLITOL® CR-H is co-processed mannitol and HPMC. It is a controlled release matrix former designed for direct compression. It is composed of 30% mannitol and 70% hypromellose type 2208.

-

PEARLITOL® GT consists of beta crystals of mannitol which are the most stable ones.

-

PEARLITOL® 100 SD and PEARLITOL® 200 SD have different particle sizes but are otherwise exactly the same product. The mean particle size of PEARLITOL® 100 SD and PEARLITOL® 200 SD are 100 µm and 170 µm respectively.

-

A reference value is available on its product profile page.

Note that the values obtained from the measurement of particle size distribution is known to vary between methods and equipment. Since each method has its own working principles and inherent limitations, the results obtained may be highly dependent on and/or specific to the method employed. Comparisons between samples should be made when the same method/procedure is employed.

-

Like PEARLITOL® SD and DC grades, PEARLITOL® GT is a direct compression grade of mannitol for instant release formulations. However, PEARLITOL® 200 GT offers enhanced flowability and tabletability, along with a reduced capping tendency. This results in greater drug load capacity and increased production rates.

-

Mannitol offers high API compatibility (no Maillard reaction thanks to the low content of reducing sugars) and no hygroscopicity, ensuring reliable and efficient drug delivery without the need for stringent handling or storage requirements.

-

PEARLITOL® Flash is a co-processed mannitol-starch excipient for direct compression having disintegrant properties. It offers excellent chemical inertness and consistent rapid disintegration time. It brings a pleasant taste and texture and is suitable for swallowable and orally dispersible tablets.

-

Crystalline mannitol powders are highly recommended for the manufacture of dry forms (granules, pellets, tablets) obtained by wet granulation. Regardless of the crystalline mannitol grade, PEARLITOL® C recrystallizes quickly in the stable crystalline form after granulation and drying. The selection of the crystalline mannitol grade can be guided by the starting particle size of the excipients in the wet granulation formulation and the desired final granule size. For example, smaller starting particle sizes generally result in smaller granules for the same process parameters. Typically, PEARLITOL® 50 C (mean particle size of approximately 50 µm) may be a suitable crystalline mannitol powders to start with in a wet granulation formulation.

-

Both the PEARLITOL® crystalline and spray-dried grades may be used in dry granulation (e.g. roller compaction) as bulking excipients. For PEARLITOL® crystalline grades (e.g., PEARLITOL® 160 C), the addition of a dry binder such as maltodextrin, microcrystalline cellulose, in the granulation formulation can help to increase the hardness significantly. As such, the combination of PEARLITOL® crystalline grades and microcrystalline cellulose is frequently a starting formulation.

-

PEARLITOL® 300 DC and PEARLITOL® 400 DC have different particle sizes but are otherwise exactly the same product. The mean particle size of PEARLITOL® 300 DC and PEARLITOL® 400 DC are 300 µm and 400 µm respectively.

-

PEARLITOL® SD consists of both alpha and beta crystals of mannitol which have been shown to be stable under practical conditions.

-

Even though PEARLITOL® has a sweet taste (approximately half the sweetness of sucrose or xylitol), it is non-cariogenic and hence, a tooth-friendly option for sugar-free formulations.

-

PEARLITOL® SD, GT and DC grades are designed for direct compression due to their superior flow and tabletability. They are available in various mean particle size grades (100 µm to 500 µm) and densities to accommodate and complement other excipients/API(s) in the formulation.

-

Due to its brittle fracture behavior during compaction, a minimum amount of 1.2% lubricant (e.g., magnesium stearate) is recommended. If other excipients are used, the concentration may be adjusted accordingly.

-

As mannitol has a brittle fracture nature, new "unlubricated" surfaces are created during compaction which gives higher and robust tablet strength. However, this potentially also leads to higher ejection forces. From our studies, a minimum amount of 1.2% lubricant (e.g., magnesium stearate) is sufficient to lower the ejection force to about 150 N to 300 N depending on the compression force and tablet shape/size.

-

PEARLITOL® mannitol is an excellent filler for moisture sensitive APIs due to its non-hygroscopicity and stable nature. DC grades are available as PEARLITOL® SD, PEARLITOL® GT and PEARLITOL® DC depending on your particle size and density requirements.