STARLAC® - LACTOSE MONOHYDRATE & MAIZE STARCH COMPOUND

StarLac®

®Registered Trademark of Meggle

- Designed for direct compression and disintegration

Co-processed lactose starch

Applications

- 1. Solid Forms - Tablets

- Swallowable Tablets

- Orally Dispersible Tablets

- 2. Solid Forms - Capsules

- Hard Capsules Fill

- 5. Other Solid Forms

- Granules and Pellets

- 3. Films and coatings

- Orally Dissolving Films

Functional properties

- Formulations Aids

- Disintegrants & Super Disintegrants

- Fillers and Binders for Direct Compression

Physical and chemical properties

- General Properties

- Multicompendial

Documents

Product Specification Sheet

Name

Region

Size

Download

STARLAC®

467,04 Ko

Region :

467,04 Ko

Safety Data Sheet

Name

Region

Language

Size

Download

STARLAC®

Europe, BE

EN

485,42 Ko

Region : Europe, BE

EN

485,42 Ko

STARLAC®

Europe, FR

EN

485,67 Ko

Region : Europe, FR

EN

485,67 Ko

STARLAC®

Europe, GB

EN

346,88 Ko

Region : Europe, GB

EN

346,88 Ko

Starlac

Americas, Asia, Oceania, Africa

EN

227,81 Ko

Region : Americas, Asia, Oceania, Africa

EN

227,81 Ko

STARLAC®

Europe, IT

EN

488,03 Ko

Region : Europe, IT

EN

488,03 Ko

STARLAC®

Europe, NL

EN

482,67 Ko

Region : Europe, NL

EN

482,67 Ko

STARLAC®

Americas, US

EN

289,27 Ko

Region : Americas, US

EN

289,27 Ko

STARLAC®

Europe, BE

DE

500,88 Ko

Region : Europe, BE

DE

500,88 Ko

STARLAC®

Europe, BE

FR

594,22 Ko

Region : Europe, BE

FR

594,22 Ko

STARLAC®

Europe, BE

NL

494,38 Ko

Region : Europe, BE

NL

494,38 Ko

STARLAC®

Europe, BG

BG

634,39 Ko

Region : Europe, BG

BG

634,39 Ko

STARLAC®

Europe, ES

ES

496,72 Ko

Region : Europe, ES

ES

496,72 Ko

STARLAC®

Europe, FR

FR

594,13 Ko

Region : Europe, FR

FR

594,13 Ko

Starlac

Americas, Asia, Oceania, Africa

ES

236,58 Ko

Region : Americas, Asia, Oceania, Africa

ES

236,58 Ko

STARLAC®

Americas, Asia, Oceania, Africa

PT

242,29 Ko

Region : Americas, Asia, Oceania, Africa

PT

242,29 Ko

STARLAC®

Americas, Asia, Oceania, Africa

RU

360,99 Ko

Region : Americas, Asia, Oceania, Africa

RU

360,99 Ko

STARLAC®

Europe, HU

HU

611,88 Ko

Region : Europe, HU

HU

611,88 Ko

STARLAC®

Europe, IT

IT

587,38 Ko

Region : Europe, IT

IT

587,38 Ko

STARLAC®

Europe, NL

NL

491,48 Ko

Region : Europe, NL

NL

491,48 Ko

Get in touch with our Technical Experts

Please feel free to contact our technical experts for support during the development process.

Technical data

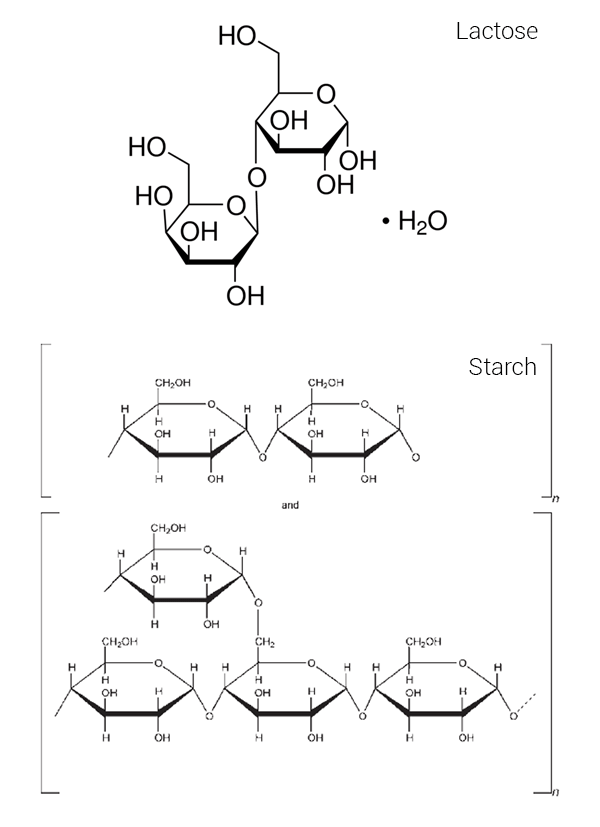

| Synonyms | Alpha-Lactose Monohydrate-Starch |

|---|---|

| Composition | Approximately Alpha-Lactose Monohydrate 85%-Native Maize Starch 15% |

| CAS number | Alpha-Lactose Monohydrate 5989-81-1Starch 9005-25-8 |

| Physical form or apperance | White or almost white odorless powder |

| Application | StarLac® co-processed lactose starch is a direct compression excipient with disintegrant properties that is also an excellent filler/binder in dry granulation process. It is suitable for swallowable and orally dispersible tablets as well as hard capsules. |

| Teste/Odor | Slightly sweet |

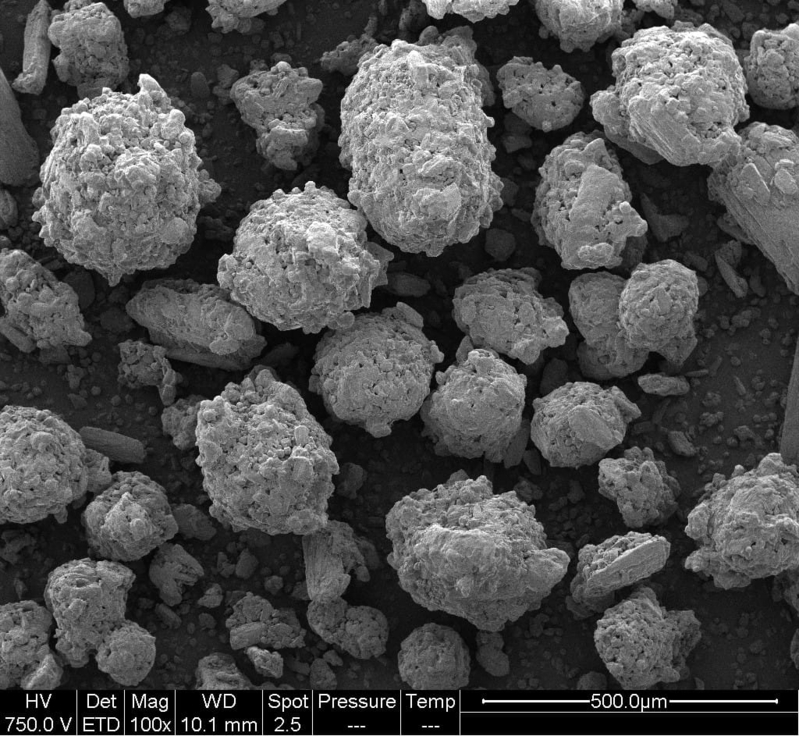

| Morphology |

|

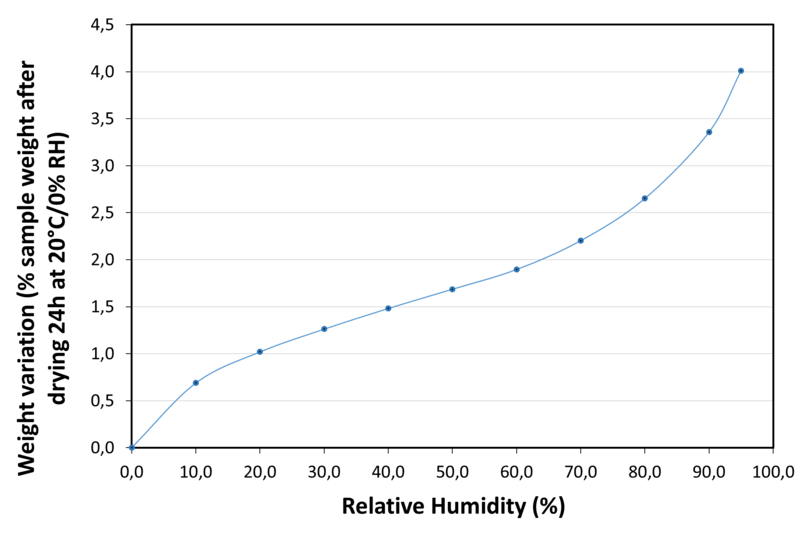

| Water sorption isotherm at 20°C |

|

| Chemical Structure |

|

| Average molecular weight | Alpha-Lactose Monohydrate: 360.31 g/mol |

| Maximal Water content (LOD) | 3.00 |

| Solubility | Partially soluble in cold water, practically insoluble in ethanol (96%) |

| Minimum melting temperature | Dehydrated alpha-lactose monohydrate: 201 °C |

| Maximum melting temperature | Dehydrated alpha-lactose monohydrate: 202 °C |

| Average mean particle diameter | 125 |

| dv10 Particle size distribution | 30 |

| dv50 Particle size distribution | 125 |

| dv90 Particle size distribution | 240 |

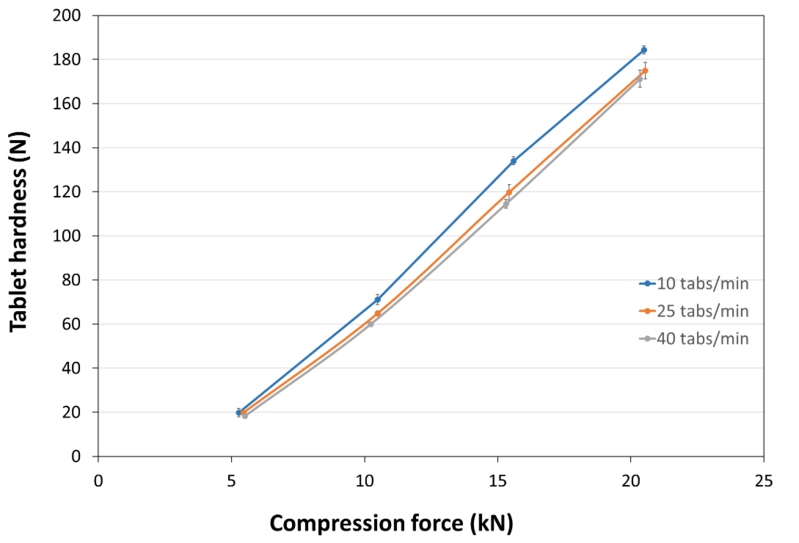

| Tablet Hardness |

|

| Experimental Conditions for Compression Behavior_Tablet Press | STYLCAM 200R |

| Experimental Conditions for Compression Behavior_Production Speed | 10, 25 and 40 tablets/min (respective linear punch velocity: 38, 96 and 152 mm/s ; respective simulated rotary press speed: 60000, 150000 and 250000 tablets/hour) |

| Experimental Conditions for Compression Behavior_Tooling | Diameter 10 mm R9 concave |

| Experimental Conditions for Compression Behavior_Formuls | 99.5% StarLac® / 0.5% magnesium stearate |

| Experimental Conditions for Compression Behavior_Tablet Mass | 455 mg |

| Powder Flowability (according to Ph.Eur. 2.9.16, 10mm outflow opening) | 4 |

| Bulk Density (g/ml) | 0.57 |

| Tapped Density (g/ml) | 0.68 |

| True Density (g/ml) | 1.50 |

| Specific Surface Area (m²/g) | 0.39 |

| Angle of Repose (°) | 28 |