Sugar-Free Double Crunch Maltitol-Coated Chewing Gum with SweetPearl® P700

Access the whole recipe, get ideas and find your plant-based ingredients for your next innovative formulation.

It's easy, you just need to create your account.

Recipe reference: LCGCCGS054

Recipe composition

| INGREDIENTS | PROPOSED RECIPE | ||

| Commercial ingredients (per batch) | Commercial ingredients (%) | End-product dry solids (%) | |

|

Sugar free crunchy chewing-gum cores with Sweetpearl® P700 & P200 |

|||

| Gum base | 8,250 kg | 16,500 | 11,550 |

| Gum base soft | 8,250 kg | 16,500 | 11,492 |

| NEOSORB® P60W, sorbitol powder* | 16,250 kg | 32,500 | 22,682 |

| SweetPearl® P700 maltitol powder* | 5,000 kg | 10,000 | 6,993 |

| SweetPearl® P200 maltitol powder* | 3,500 kg | 7,000 | 4,895 |

| XYLISORB® 90 xylitol powder* | 3,500 kg | 7,000 | 4,875 |

| LYCASIN® 85/55 maltitol syrup* | 3,500 kg | 7,000 | 4,165 |

| Glycerin | 0,100 kg | 0,200 | 0,140 |

| Citric acid, anhydrous | 0,750 kg | 0,500 | 0,350 |

| Flavor, liquid | 0,750 kg | 1,500 | 1,050 |

| Flavor, powder | 0,500 kg | 1,000 | 0,665 |

| Sucralose | 0,100 kg | 0,200 | 0,140 |

| Acesulfame K | 0,050 kg | 0,100 | 0,070 |

| Total | 50,000 kg | 100,000 | 69,067 |

| Sugar free Hard coating: SweetPearl® P200 and SweetPearl® P35 | |||

|

Sugar free Maltitol coating white solution: SwetetPearl® P200 |

27,201 kg | 92,202 | 26,632 |

| SweetPearl® P35 maltitol powder* | 1,992 kg | 6,752 | 2,786 |

| Flavor, liquid | 0,299 kg | 1,013 | 0,418 |

| Carnauba wax | 0,010 kg | 0,034 | 0,014 |

| Total | 29,502 kg | 100,000 | 29,850 |

| Sugar free Maltitol coating white solution: SweetPearl® P200 | |||

| SweetPearl® P200 maltitol powder* | 17,803 kg | 65,450 | 24,900 |

| Gum arabic solution 40% | 2,380 kg | 8,750 | 1,333 |

| Tianium dioxide | 0,286 kg | 1,050 | 0,400 |

| Water | 6,732 kg | 24,750 | 0,000 |

| Total | 27,201 kg | 100,000 | 26,632 |

| Sugar free double crunch maltitol coated chewing-gum | |||

| Sugar free crunchy chewing-gum cores with Neosorb® P60W, Xylisorb® 90 and SweetPearl® P700 & P200 |

50,000 kg | 70,000 | 69,067 |

| Sugar free Hard coating: SweetPearl® P200 and SweetPearl® P35 | 21,429 kg | 30,000 | 29,850 |

| Residual moisture | - | - | 1,082 |

| Total | 71,429 kg | 100,000 | 100,000 |

*Roquette product

Process method

Loading Procedure (min) - Z blade kneader at 50oC - 60 kg batch

0 min: Introduce the melted gum base (stove overnight at 50oC) and half of he NEOSORB® P60W.

3 min: Introduce Xylitol 90

5 min: Add the LYCASIN® 85/55 Maltitol syrup

7 min: Add half of the Neosorb® P60W and aspartame

10 min: Add the glycerin

11 min: Add the liquid flavoring

13 min: Add the powder flavoring, acid, SweetPearl® P700 - P200,

15 min: Unload the kneader (gum paste at around 530C).

Divide the gum batch into approx. 2 kg loaves. Store them at 20oC-50% RH for around one hour (loaves at around 40oC when raching the extrude).

Extrusion: (Togum TO-E82)

Body of the extruder at 39oC

Head of the extruder at 42oC

Rolling & Scoring: 4pairs rollers & scoring: 2 pairs rollers (Togum TO-W191)

Gum strip dusted with blend 75/25 talcum/mannitol 60

Conditioning:

Store the strip of not fully separated tablet centers at around 15oC - 50% RH for another 48 hours before coating them.

Coating

Coating solution preparation:

Pour the polyol in the cold water, heat until 80-90oC under agitation and wait for complete dissolution.

Add the gum arabic solution.

Add the color (titanium dioxide) under agitation.

Check and adjust the brix at 70% Dry Substance.

maintain the temperature at 70-75oC.

Coating protocol:

See annex page

Ingredients list and allergens (Indicative)

- Sweeteners (maltitol, sorbitol, maltitol syrup, xylitol, sucralose, acesulfame potassium)

- Gum base

- Flavor

- Thickener (gum arabic)

- Color (titanium dioxide)

- Acid (citric acid)

- Humectant (glycerin)

- Glazing agent (carnauba wax).

Label of nutrition facts (Indicative)

| Average nutrition facts |

Per serving Proposed recipe |

Per 100 g Proposed recipe |

| Energy (kcal) | 2 | 176 |

| Fat (g) | 0.0 | 0.0 |

| of which saturates (g) | 0.0 | 0.0 |

| Carbohydrate (g) | 1.0 | 71.5 |

| of which sugars (g) | 0.0 | 0.0 |

| of which polyols (g) | 1.0 | 71.2 |

| Fiber (g) | 0.0 | 1.3 |

| Protein (g) | 0.0 | 0.0 |

| Salt (g) | 0.00 | 0.00 |

Comments

Recipe can be adjusted for Mint or Fruit flavor.

Coating

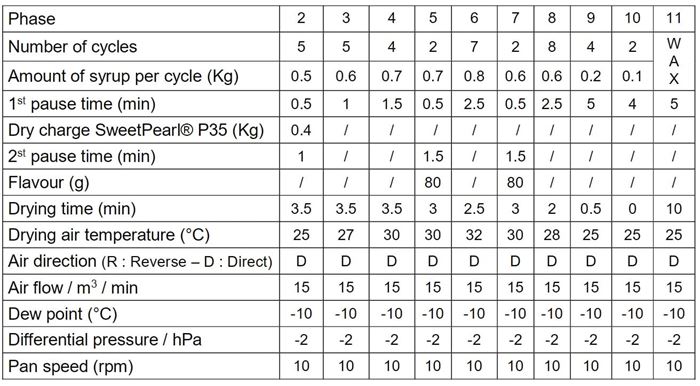

COATING PROTOCOL (COATING PAN: DRIACOTER 1200)

COATING SEQUECES (FOR 50 KG GUM CENTERS)

PHASE 1 = DEDUSTING OF THE CENTERS - AIR PREHEATING

- Coating time (including waxing): 3 h 30 min

- Ratio coating weight / chewing-gum weight = 30 / 70

Disclaimer

This formula is a guideline for recommended uses of our products. It does not imply consent to any use in violation of existing patents. This is for your information only, we believe it to be reliable.