Optimizing API Load and Minimizing Tablet Weight Leveraging an Innovative DC Mannitol

Published January 27, 2026

Presented at the 14th World Meeting on Pharmaceutics, Biopharmaceutics and Pharmaceutical Technology, 18 - 21 March 2024, Vienna, Austria.

Authors

Philippe Lefèvre

Head of Global Pharma Applications Labs, Roquette

Nicolas Descamps

Manager of the Functional Properties Analytical Laboratory, Roquette R&D

Sébastien Croquet

Application Scientist, Roquette

Tessa Van Der Oost

Roquette France CTS Lab Intern

Steve Amoussou-Guenou

Global Technical Developer Pharma Solutions

Introduction

Tablets with stability issues often use mannitol, a stable, water-soluble excipient compatible with most drugs. Direct compression is a preferred method for its simplicity and cost-effectiveness. However, directly compressible mannitol grades have a high tendency to capping1, especially with increased tableting speed or compression forces. Solutions to overcome capping include precompression steps, reduced production speed, or lower compression force, but often require reducing the API load for satisfactory production yield.

OBJECTIVES

PEARLITOL® 200 GT is an innovative granulated beta mannitol for direct compression which properties have been optimized to improve tabletability and limit the occurrence of capping. It was demonstrated that the high powder density of this new and innovative directly compressible mannitol, among other properties, explains its unique feature of improving tabletability and suppressing tablet capping.2

The main benefit of improved tabletability is the possibility to increase the API load, with two beneficial consequences:

- Increase the API dosage for the same tablet weight.

- Decrease the weight and size of tablet for a given API dosage.

Sertraline was used as model API with poor tabletability. Increasing API loads were tested with and without precompression, using a spray-dried mannitol as reference direct compression (DC) mannitol to quantify the API ratio increase or tablet weight decrease when moving to PEARLITOL® 200 GT.

Materials and Methods

Materials

Granulated mannitol: PEARLITOL® 200 GT (GTman), spray-dried mannitol: PEARLITOL® 200 SD (SDman), both from Roquette Frères (Lestrem, France); Roquette Magnesium Stearate from Roquette Frères (Lestrem, France); Sertraline: StarPharm (China).

Methods

Blending

Mannitol and sertraline were mixed for 5 min in a Turbula mixer (WAB-Group, Muttenz, Switzerland). Additional mixing for 5 min was done after adding the magnesium stearate.

Powder characteristics

Bulk density (BD) and tapped density (TD) were measured and Hausner ratio (HR) calculated as per European Pharmacopeia 2.9.34.

Powder flow time (FT) and angle of repose (AR) were measured as per European Pharmacopeia 2.9.16.

Tableting

All tableting trials were done on a high-speed rotary tablet press simulator: STYLCAM 200R (MEDELPHARM), using KORSCH XL400 profile.

Punches/Die: Euro B Elizabeth D10R10

Tablet weight: 400 mg

Lubrication: 1% magnesium stearate

Compression force: 5, 10, 15, 20 kN

Precompression force: 0 or 20% of the compression force

Simulated tableting speed: 85,000 tablets/hour.

Tablet characterization

All tablets were visually inspected; capped tablets are recorded without any further characterization. Per test, 10 tablets were analyzed on their dimensions, weight, and hardness, using a Pharmatron ST 50 (Sotax) equipment.

Results And Discussions

The sertraline powder had very poor powder flow properties and was not usable on a rotary tablet press. Blends with SDman were free flowing up to 15% sertraline (see table 1). The blend with 20% sertraline was not free flowing and to avoid inconsistent die feeding, a force feeder was used for all trials on a tablet press simulator.

Table 1. Powder characteristics of sertraline/SDman blends

| Sertraline/SDman mass ratio | Bulk density (g/cm3) | Tapped density (g/cm3) | Hausner ratio (-) | Angle of repose (°) | Flow time (s) |

| 0/100 | 0.513 | 0.610 | 1.19 | 32 | 5 |

| 5/95 | 0.569 | 0.646 | 1.14 | 31 | 4 |

| 10/90 | 0.556 | 0.662 | 1.19 | 36 | 4 |

| 15/85 | 0.547 | 0.658 | 1.20 | 38 | 5 |

| 20/80 | 0.577 | 0.702 | 1.22 | 38 | infinite |

| 100/0 | 0.455 | 0.676 | 1.49 | 54 | infinite |

GTman possesses better flow properties than SDman and blends with sertraline were free flowing up to 25% (table 2). Tablets were produced up to 40% sertraline, but an improvement of the flow will be required for an industrial production, for example by adding a glidant.

Table 2. Powder characteristics of sertraline/GTman blends

| Sertraline/SDman mass ratio | Bulk density (g/cm3) | Tapped density (g/cm3) | Hausner ratio (-) | Angle of repose (°) | Flow time (s) |

| 0/100 | 0.650 | 0.750 | 1.15 | 29 | 4 |

| 5/95 | 0.67 | 0.75 | 1.12 | 30 | 3 |

| 10/90 | 0.684 | 0.773 | 1.13 | 29 | 3 |

| 15/85 | 0.690 | 0.821 | 1.19 | 28 | 3 |

| 20/80 | 0.685 | 0.834 | 1.22 | 32 | 4 |

| 25/75 | 0.685 | 0.848 | 1.24 | 33 | 9 |

| 30/70 | 0.645 | 0.862 | 1.34 | 39 | infinite |

| 35/65 | 0.606 | 0.855 | 1.41 | 42 | infinite |

| 40/60 | 0.608 | 0.864 | 1.42 | 42 | infinite |

| 100/0 | 0.455 | 0.676 | 1.49 | 54 | infinite |

The tableting study was carried out in two stages: first trials without precompression then trials with precompression. Logically, tableting of powder blends with tendency to capping is done using a precompression step. It was expected that precompression being used to limit the capping will decrease the difference between the two DC mannitol grades.

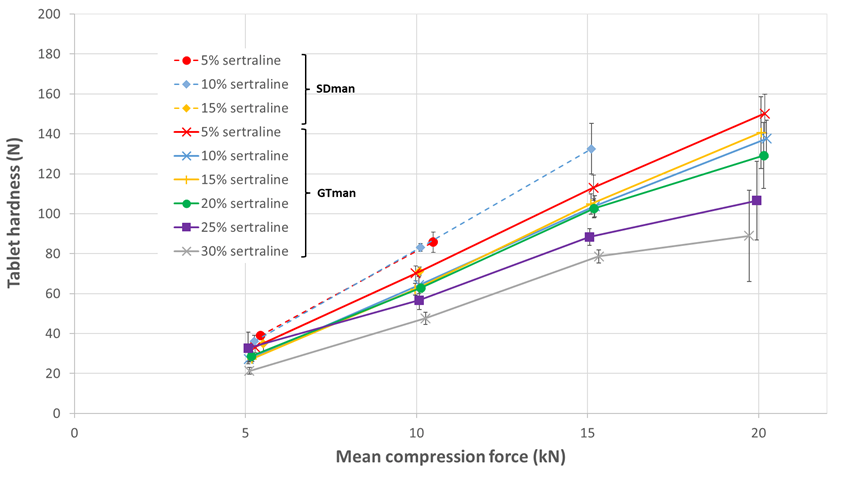

In the absence of precompression, SDman exhibited capping at every sertraline ratio. As the sertraline content increased, the compression force threshold for capping appearance decreased (capping at 20 kN compression force for 5% and 10% sertraline and 15 kN compression force for 15% sertraline (see figure 1). In these conditions, 100 N tablet hardness was accessible with 5 and 10% and not with 15% sertraline. With GTman, no capping was observed up to 25% sertraline ratio. At 30% sertraline ratio capping appeared at 20 kN compression force (high standard deviation of the tablet hardness). And with the decrease of tablet hardness due to the API ratio increase, a tablet hardness of 100 N was not reachable above 25% sertraline ratio.

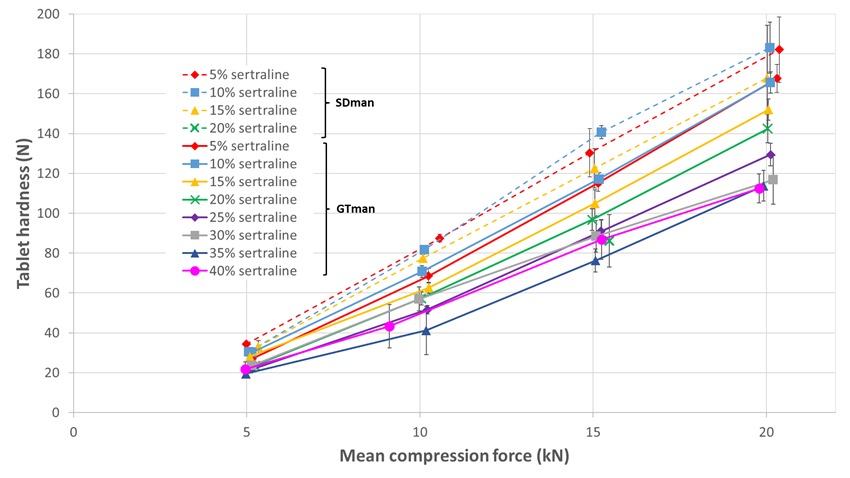

Utilizing precompression, SDman began to show capping at 15% sertraline (with a high standard deviation of tablet hardness at 20 kN compression force), and tablets were not viable at 20% sertraline (as seen in figure 2). A tablet hardness of 123 N was achieved with 15% sertraline and a 15 kN compression force.

Figure 1: Tablet hardness vs compression force at increasing sertraline ratio without precompression force.

Dotted line: SDMAN. Solid line: GTman.

With GTman, acceptable tablets could be produced without capping up to 40 % sertraline content. Tablet hardness was observed to decrease with increasing sertraline ratio.

Figure 2: Tablet hardness vs compression force at increasing sertraline ratio with precompression force.

Dotted line: SDMAN. Solid line: GTman.

Conclusion

This study on tablet formulation with sertraline showed that using a DC mannitol with optimal tabletability offers the opportunity to increase API load or decrease tablet weight. Indeed, it was possible to load more API (+100 to 166%) when using PEARLITOL® 200 GT for the same tablet weight. Alternately, tablet weight could be reduced as well (-50% to -62%) while keeping the same API load (table 3).

Table 3. Impact of API ratio increase on API content or on tablet weight.

| Without precompression | With precompression | |||

| Mannitol grade | SDman | GTman | SDman | GTman |

| Sertraline ratio | 10 % | 20 % | 15 % | 40 % |

| API content for 400 mg tablet | 40 mg | 80 mg | 60 mg | 160 mg |

| API dosage increase | +100% | +166% | ||

| Tablet weight for 50 mg API | 500 mg | 250 mg | 333 mg | 125 mg |

| Tablet weight decrease | -50% | - 62% | ||

References

- Tarlier N., Lefèvre P., Simon D., Characterization of different textured mannitol tabletability using a rotary tablet press simulator, Poster Compaction Simulation Forum, Ghent (2017)

- Lefèvre, P., Haeusler, O., Boit, B., Croquet, S., Comparison of capping tendency of directly compressible mannitol powders, Poster, 4th European Conference on Pharmaceutics, 20-21 March 2023, Marseille, France.

® Registered trademark(s) of Roquette Frères.

The information contained in this document is to the best of our knowledge true and accurate, but all instructions, recommendations or suggestions are made without guarantee. Since the conditions of use are beyond our control, we disclaim any liability for loss and/or damage suffered from use of these data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with these data or suggestions infringes any patent. No part of this document may be reproduced by any process without our prior written permission.