How to produce jelly and wine gums

Published February 19, 2026

Overview of the different categories of jellies and of a typical mogul process. Focus on a critical point: the starch cooking.

Overview of different ranges

The jelly/gummy and starch gum or wine gum market is characterized by various shapes, textures, colors, and flavors that give to this category of candies a “ludic” image.

How to distinguish the main textures:

Jellies / Gummies

| |

Wine gums

| |

Hard gums

| |

Pectin jellies

|

The typical mogul jelly process: moulding

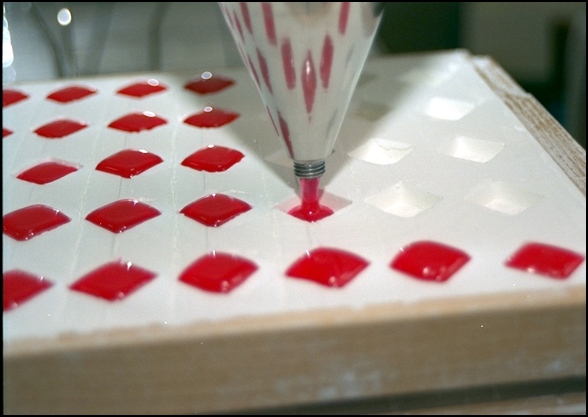

These confections are usually deposited in moulding starch with a “mogul.”

A starch mogul is a machine that makes shaped candies or candy centers from syrups or gels, such as gummy candy. These softer candies and centers are made by filling a tray with corn starch, stamping the desired shape into the starch, and then pouring the filling or gel into the holes made by the stamp. When the candies have been set, they are removed from the trays, and the starch is recycled. Starch moguls were invented around 1899 and were in everyday use within a decade or two.

(source: Wikipedia)

The significant advantage of this technology is the flexibility for changing the shapes of the finished products and the ease of removing water from the deposited candy using the starch as a water attractor.

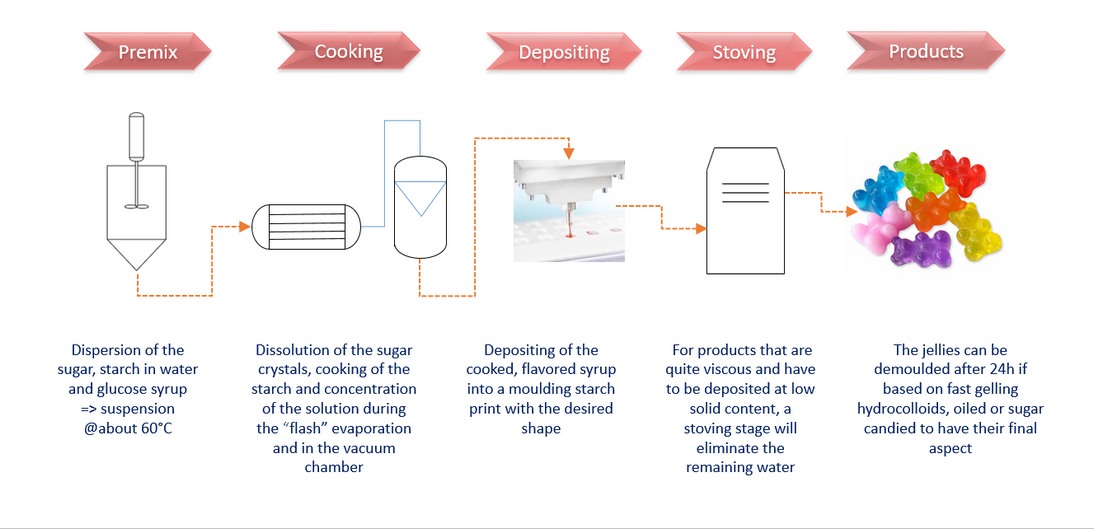

See below the main steps in a jelly-type product production:

Focus on the cooking stage:

Depending on the type of confection, the cooking stage will be crucial to control to obtain the right final texture:

- Gelatin does not require a special change of “state” during the cooking (apart from good dissolution) but could be degraded with high temperature. Therefore, because of a long cooking time at high temperature, the gelatin will be added as a solution after cooking.

- Gum arabic is heat stable.

- Pectin is heat stable but has a high-temperature gelling point. This means that the jellification will start as soon as the temperature is decreasing: the depositing hoppers must be maintained at 90°C.

- Starch is generally introduced in the premix as crystalline granules. We will use the water introduced in the recipe and the heat of cookers to swell the granules. When it is swollen to the right extend, the jellification will be optimum. This is why is it important to control the cooking process well.

Different stages of starch cooking:

| Uncooked starch can be recognized with the typical malt cross, visible under a polarized light microscope. At this stage, the starch will not bring any viscosity; the slurry will be opaque/white. | |

| Thanks to the presence of “free” water and the effect of the heat, the starch granules will start to absorb water and swell. At this stage, the viscosity starts to increase (which is a good indicator of the starch cooking stage) and becomes more transparent. The maximum swelling will give the maximum jellification as well as the maximum viscosity that could be an issue for the depositing stage. This is why Roquette offers a wide range of thin boiling starches (CLEARGUM®), developed especially for wine gum and jelly without gelatin. | |

| If the heating is too intense and/or too much water remains available, the granules will swell to a higher extent and burst. The granules’ wall will collapse, freeing up the amylose and amylopectin molecules. Consequently, the viscosity will drop down. This early stage of “bursting” could be an indicator that all the granules are well swollen, and some of them are starting to burst. The advantage of the viscosity decrease is to ease the depositing. However, if the heating is prolonged further and all the granules are burst, the jellification capacity will decrease after cooling. |

This is why it is necessary to have good control of the cooking stage to take the best advantage of the starches for multiple sensorial experiences and to facilitate the depositing stage.